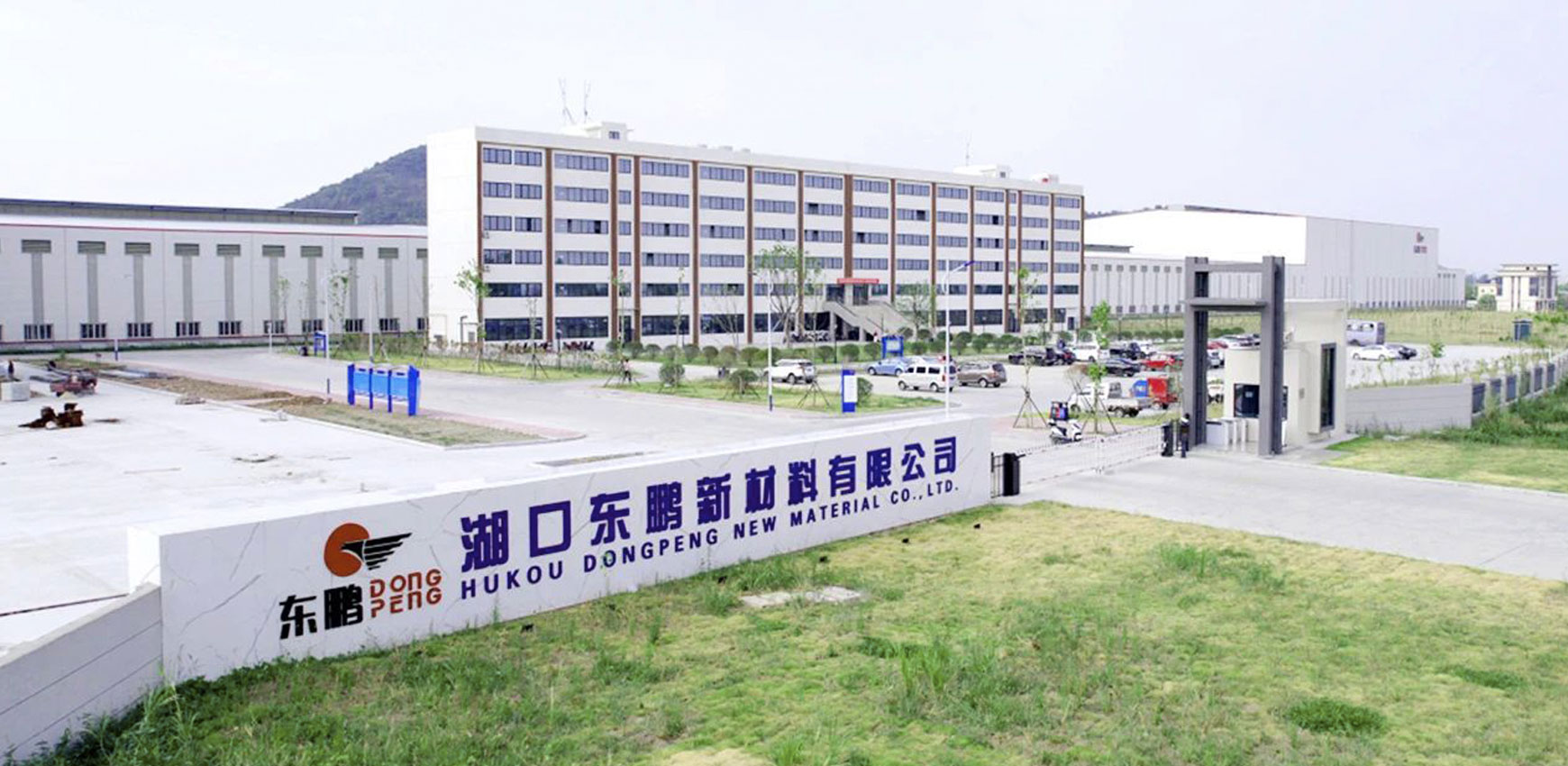

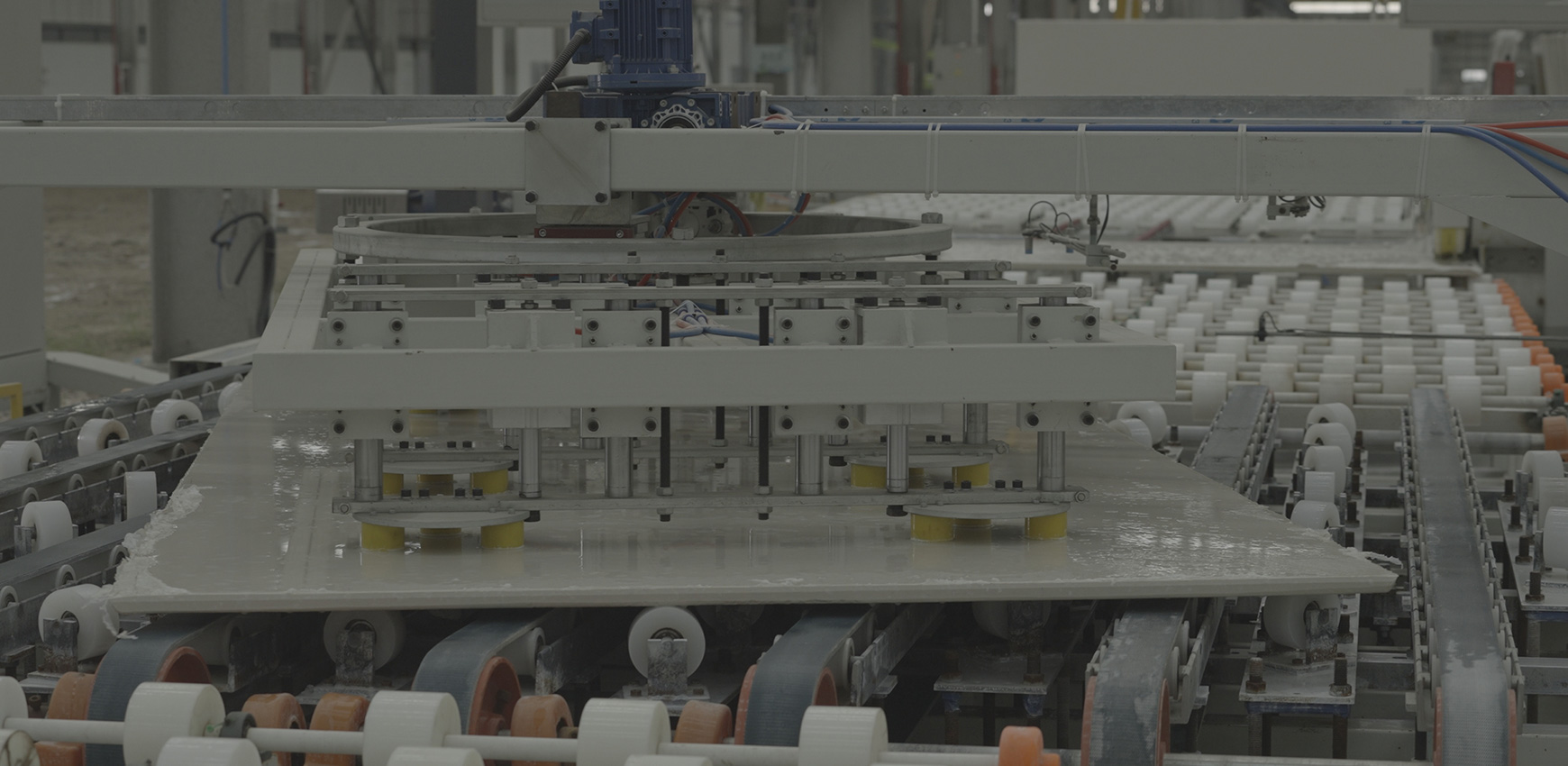

Dongpeng vigorously promotes green manufacturing and sustainable development. The Dongpeng Hukou Base is a smart factory built in accordance with the "Made in China 2025" standards. It is the industry's first factory to fully independently develop complete sets of intelligent equipment. It is also among the first batch of Green Factory demonstration units designated by the Ministry of Industry and Information Technology and has been awarded the title of "National-Level Green Factory".

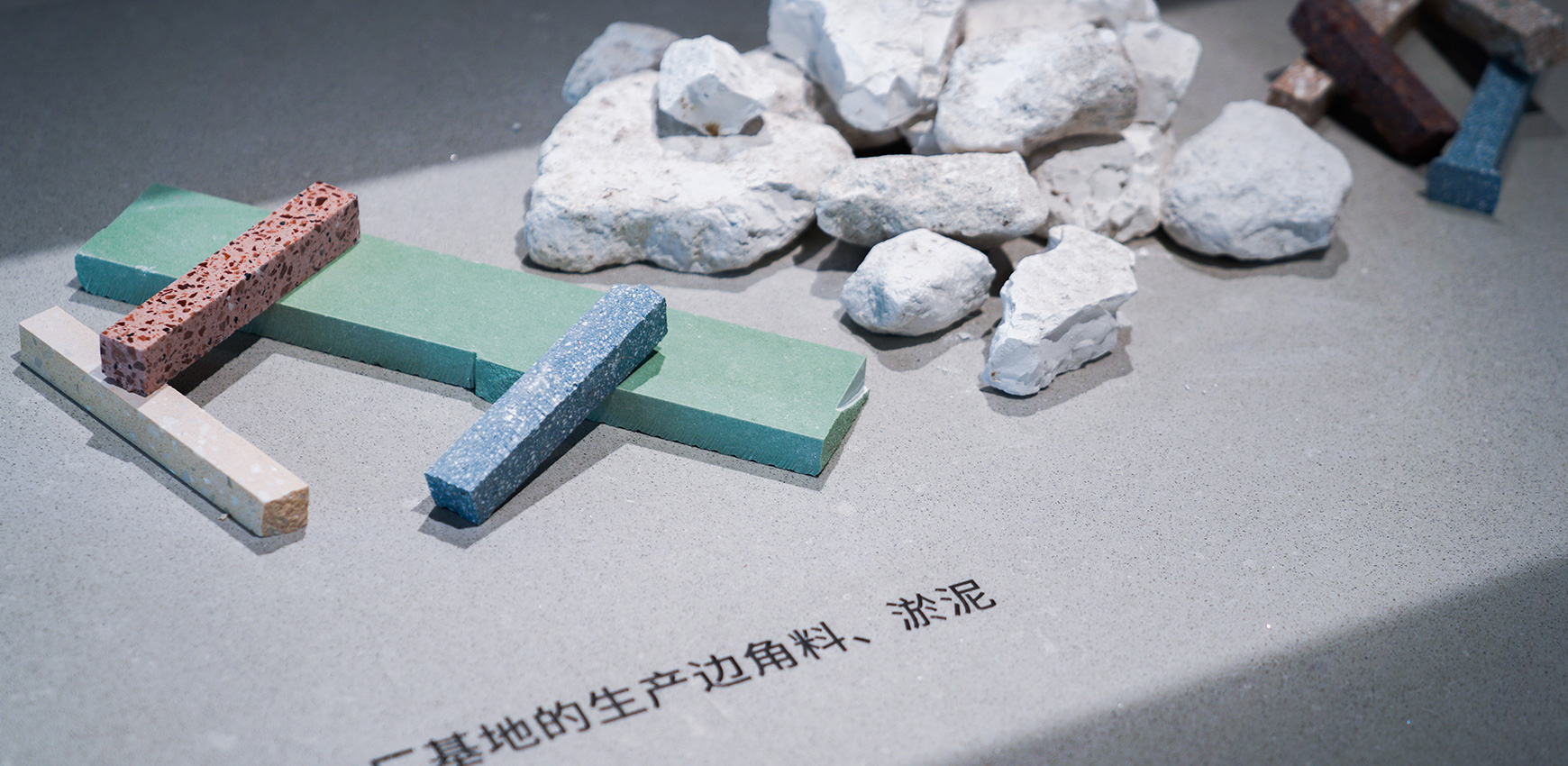

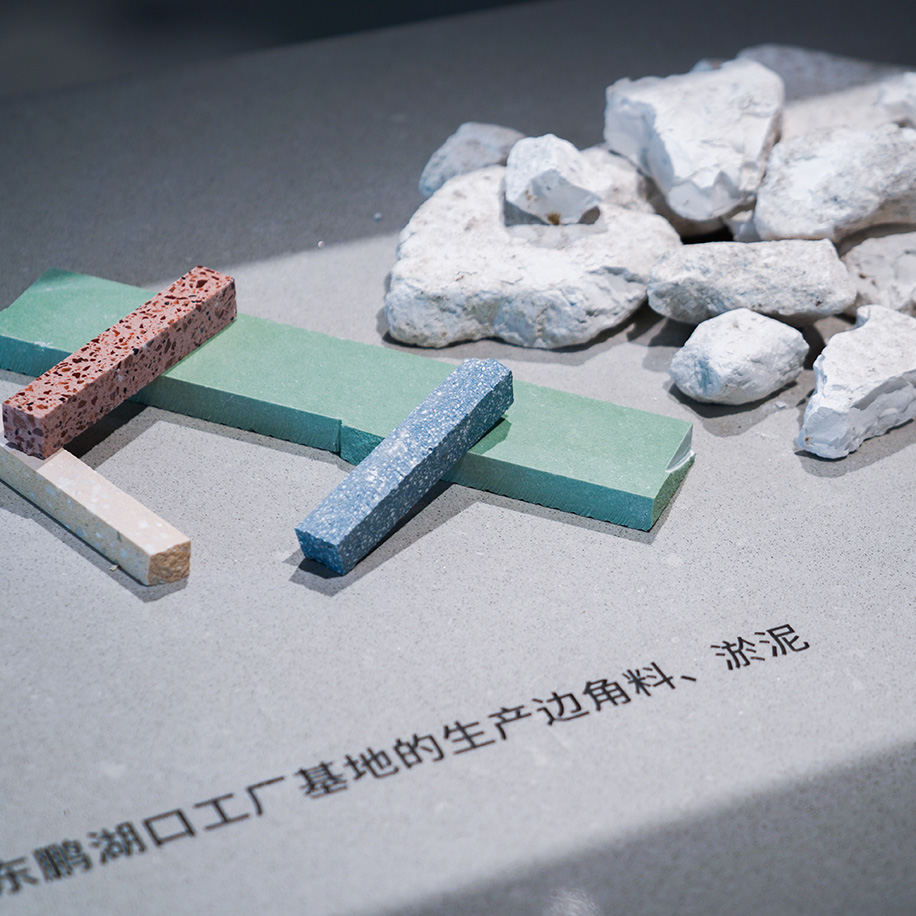

Following the 3R concept (Reduce, Reuse, Recycle), the Hukou Base covers an area of 600 mu. It is planned to house 15 eco-stone production lines, with an annual production capacity reaching 15 million square meters. Utilizing Industry 4.0 technology, it integrates a circular system with strengths in energy conservation and emission reduction. The base enables stable mass production and controllable quality of finished products. The production process is firing-free, low-energy, low-emission, and pollution-free, leading and driving high-quality development in the industry. It represents a modern, new-technology environmental protection industry highly valued by government authorities.